.png?width=624&height=517&name=ice-ring-FT7%20(1).png)

Acu-Res® Technology

FT’s unique acoustic resonance (Acu-Res®) technology is trusted for critical control systems the world over. Acu-res® wind sensors automatically compensate for changes in the air’s temperature, pressure and humidity to maintain data continuity.

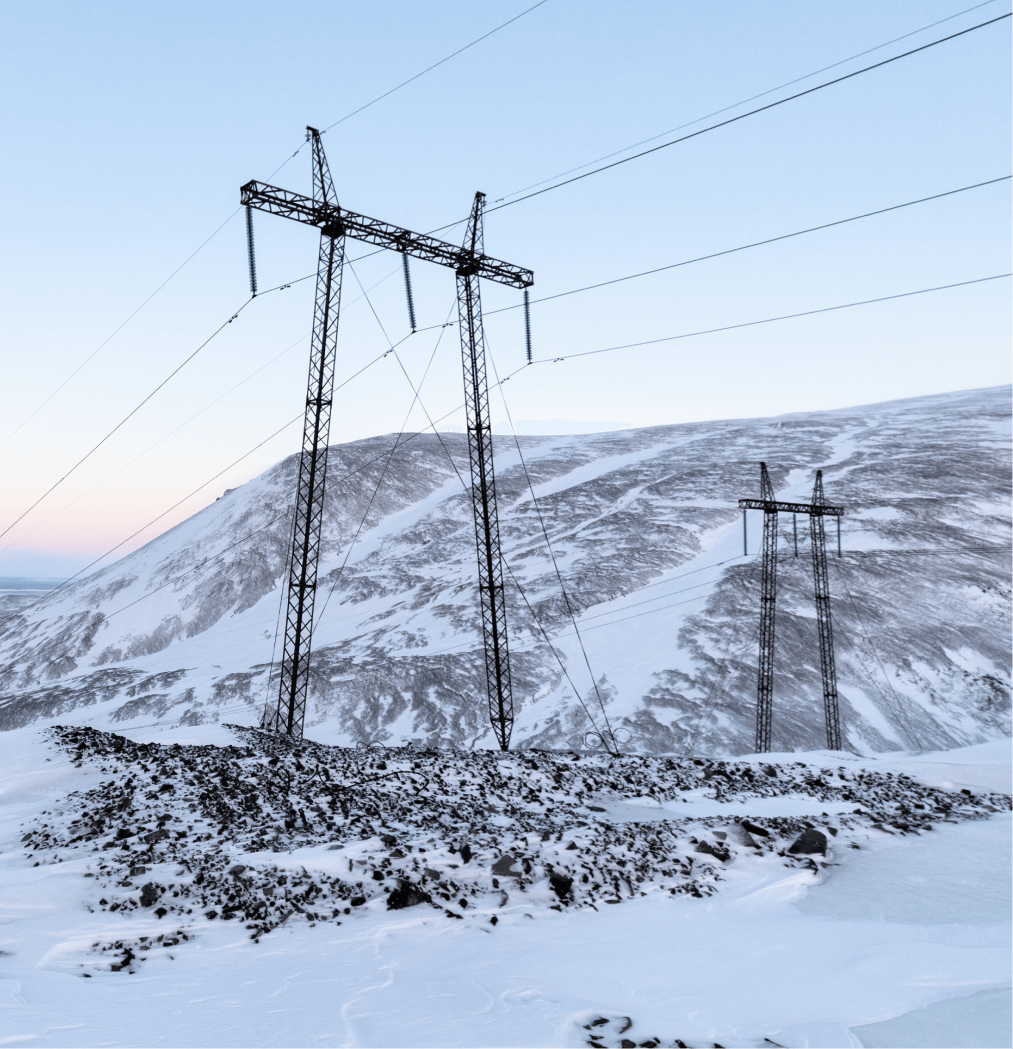

Enduring the world’s toughest weather

FT wind sensors have been proven to provide reliable data in extreme environments, from offshore wind farms to Icelandic power-line transmission. Sealed to IPX6K, corrosion resistant, surge protected and powerful heating for ice-free operation.

Why choose ft

From initial goods inspection to calibration and testing, quality is at the heart of FT Technologies’ manufacturing principles. FT is ISO 9001 and ISO 14001 accredited and adheres to APQP4 Wind for new product development.

Reading wind speeds from 0 to 90m/s and outputting data at 10Hz, FT’s unique Acu-Res® technology gives you precise wind measurements with no delay.

Hard-anodised aluminium, waterproof housings, industrial-grade connectors, and all-body heating ensures FT wind sensors provide reliable wind speed and direction data, even in extreme conditions.

Applications

With industry-leading quality control measures in place, FT technologies manufactures professional-grade wind sensors that are chosen for a range of demanding applications. Whether you want to upgrade your wind turbines, gain weather warnings for critical infrastructure or get accurate wind data for your autopilot, FT wind sensors ensure you receive reliable data 24 hours a day, 365 days a year.

control systems

Making precise adjustments to your equipment based on wind speed and wind direction means you need data that you can rely on. FT wind sensors bring the latest developments in software processing and aeroacoustics to give you the best performance, efficiency and reliability at all times.

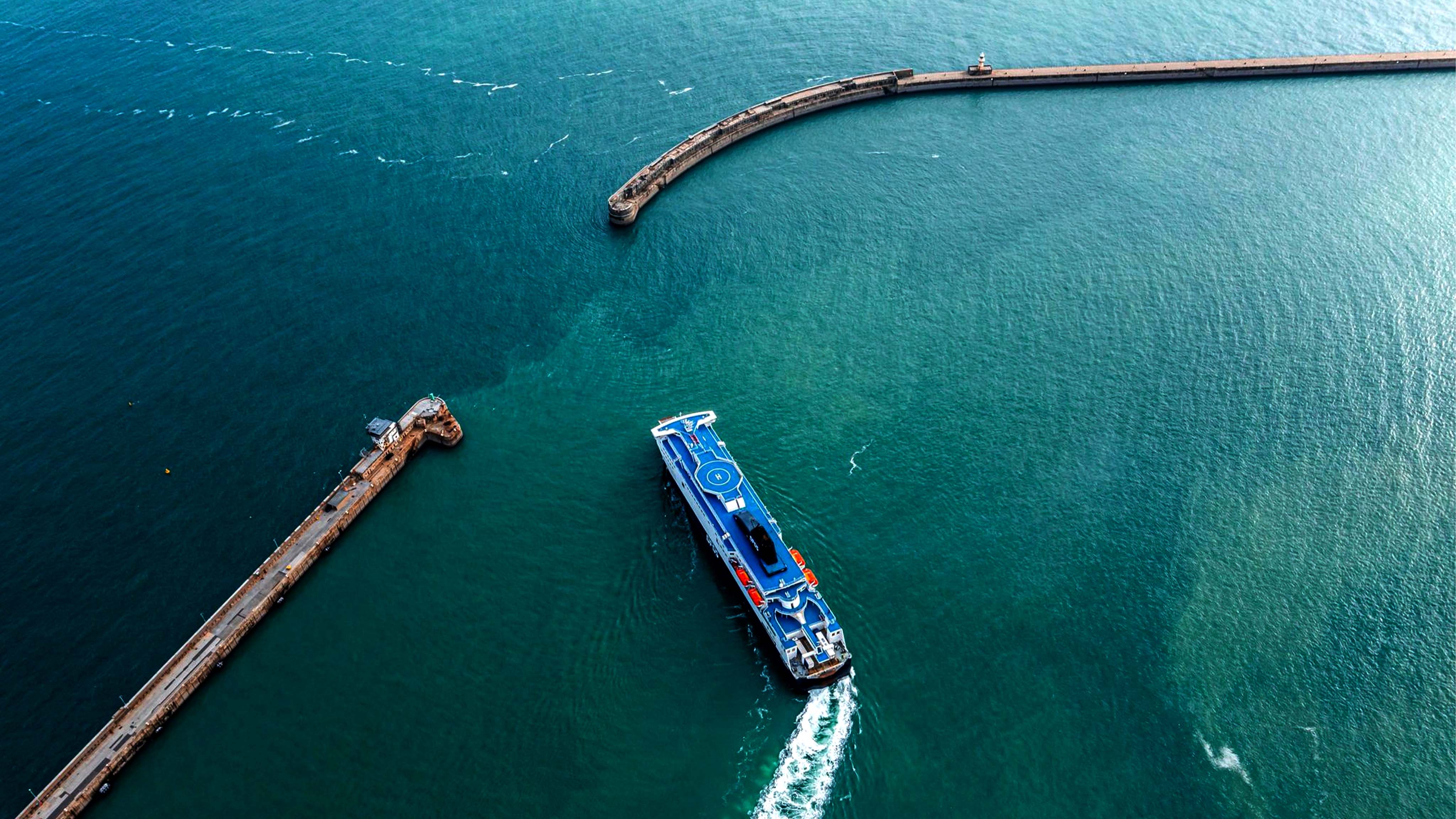

navigation systems

Accurate wind data is essential for both partial and fully automated navigation systems, enhancing route optimisation, energy conservation, and safety. By integrating real-time wind speed and direction, vessels can adjust their course to minimise drag, reduce fuel consumption, and avoid hazardous conditions. With advanced wind sensors providing reliable, up-to-date information, navigation systems can make precise decisions, leading to smoother operations and lower operational costs.

safety warnings

Wind sensors are vital components of safety systems across various industries, providing real-time, accurate data on wind speed and direction. This information is crucial for preventing accidents, safeguarding structures, and ensuring safe operations in challenging environments, from construction sites to transportation networks. By enabling precise adjustments or emergency shutdowns during high winds, these sensors help maintain safety standards, minimise risks, and enhance operational reliability. Discover how FT’s advanced wind sensors deliver the critical data needed to protect lives and assets in wind-sensitive applications.

weather monitoring

Wind sensors are essential for weather monitoring applications such as air quality analysis, methane leak detection, and dynamic line rating. Accurate wind data enables the tracking of pollutant and methane dispersion, supporting effective environmental management and safety measures. For dynamic line rating, precise wind speed and direction measurements optimise power grid efficiency by calculating real-time line capacity. FT wind sensors deliver reliable, high-resolution data, ensuring dependable performance across these diverse applications.

marine

Wind sensors are indispensable in marine environments, providing accurate wind speed and direction data critical for safety, efficiency, and performance. On commercial ships, they optimise navigation and enhance operational safety, even in harsh oceanic conditions. For offshore buoys, wind sensors deliver essential weather and ocean monitoring data, enduring constant exposure to saltwater and rough seas. In performance sailing, they offer the precision needed for tactical decisions while withstanding the physical stresses of racing. FT’s durable, corrosion-resistant wind sensors are engineered to deliver reliable, maintenance-free operation in demanding marine environments, ensuring consistent data across all applications.

35 years of experience

FT Technologies has been designing and manufacturing acoustic resonance wind sensors for over 35 years. As a leading supplier to the wind turbine industry for more than 20 years, we design and manufacture all our wind sensors in the UK and export them globally.

FT7 Series

FT7 Series wind sensors are the fit-and-forget solution for maintenance-free operation year-round, even in the harshest conditions.

.png?width=1120&height=908&name=Image%20(1).png)

FT6 Series

FT6 Series wind sensors are designed for professional performance while minimising weight impact on the end user.

WHAT OUR CUSTOMERS SAY

The FT205, mounted on our drone, worked perfectly in real fire situations. The data it produced proved critically important to the emergency services as they were able to predict the spread of the blaze during the night.

Javier Prada Delgado

Dronetools SL

After hearing about the reliable performance of the FT sensor and then holding it in my hand and feeling the difference in weight and size, I was convinced. The weather can throw anything at us now. Changing to the FT sensor has made it possible to keep these turbines running, even in our coldest winter conditions.

Guy Le Blanc

Minnesota Wind Farm

The FT wind sensor was the only one to survive – the other two ultrasonic wind sensors were so badly damaged they stopped working altogether. The FT sensor, however, remained ice-free and continued giving measurements, and that was one of the worst icing events we have ever seen at the observatory.

Cesar Lopez

Sieltec Canarias

During the second night of the transatlantic race to New York my [mechanical] wind sensor stopped working and I switched to the [FT] sensor. I was really happy to have the sensor on, initially as a back up and then becoming my primary and only wind sensor. I was happily surprised as I found the sensor gave accurate and good numbers, allowing the autopilot to work really well while steering in wind mode. During the race I was not the only boat to have the [mechanical] wind sensors stop working, I was really pleased with the reliability and would go as far as to say it has been the most reliable sensor I have seen so far withstanding the violent conditions it sees at the top of the mast.

Amélie Grassi

Professional Sailor (Navigatrice)

The FT205, mounted on our drone, worked perfectly in real fire situations. The data it produced proved critically important to the emergency services as they were able to predict the spread of the blaze during the night.

Javier Prada Delgado

Dronetools SL

After hearing about the reliable performance of the FT sensor and then holding it in my hand and feeling the difference in weight and size, I was convinced. The weather can throw anything at us now. Changing to the FT sensor has made it possible to keep these turbines running, even in our coldest winter conditions.

Guy Le Blanc

Minnesota Wind Farm

The FT wind sensor was the only one to survive – the other two ultrasonic wind sensors were so badly damaged they stopped working altogether. The FT sensor, however, remained ice-free and continued giving measurements, and that was one of the worst icing events we have ever seen at the observatory.

Cesar Lopez

Sieltec Canarias

During the second night of the transatlantic race to New York my [mechanical] wind sensor stopped working and I switched to the [FT] sensor. I was really happy to have the sensor on, initially as a back up and then becoming my primary and only wind sensor. I was happily surprised as I found the sensor gave accurate and good numbers, allowing the autopilot to work really well while steering in wind mode. During the race I was not the only boat to have the [mechanical] wind sensors stop working, I was really pleased with the reliability and would go as far as to say it has been the most reliable sensor I have seen so far withstanding the violent conditions it sees at the top of the mast.

Amélie Grassi

Professional Sailor (Navigatrice)

The FT205, mounted on our drone, worked perfectly in real fire situations. The data it produced proved critically important to the emergency services as they were able to predict the spread of the blaze during the night.

Javier Prada Delgado

Dronetools SL

After hearing about the reliable performance of the FT sensor and then holding it in my hand and feeling the difference in weight and size, I was convinced. The weather can throw anything at us now. Changing to the FT sensor has made it possible to keep these turbines running, even in our coldest winter conditions.

Guy Le Blanc

Minnesota Wind Farm

The FT wind sensor was the only one to survive – the other two ultrasonic wind sensors were so badly damaged they stopped working altogether. The FT sensor, however, remained ice-free and continued giving measurements, and that was one of the worst icing events we have ever seen at the observatory.

Cesar Lopez

Sieltec Canarias

During the second night of the transatlantic race to New York my [mechanical] wind sensor stopped working and I switched to the [FT] sensor. I was really happy to have the sensor on, initially as a back up and then becoming my primary and only wind sensor. I was happily surprised as I found the sensor gave accurate and good numbers, allowing the autopilot to work really well while steering in wind mode. During the race I was not the only boat to have the [mechanical] wind sensors stop working, I was really pleased with the reliability and would go as far as to say it has been the most reliable sensor I have seen so far withstanding the violent conditions it sees at the top of the mast.

Amélie Grassi

Professional Sailor (Navigatrice)